Introduction

In today’s competitive market, optimizing operational efficiency and controlling costs are more crucial than ever. One of the most effective ways to achieve this is through the strategic selection of forklifts. This post explores how choosing the right forklift model and specifications can significantly impact your return on investment (ROI), with insights drawn from industry case studies and detailed ROI calculations.

Understanding Your Needs

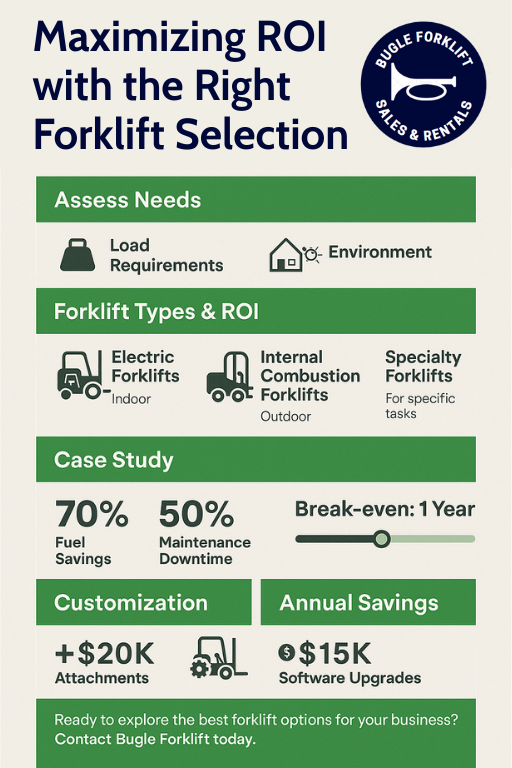

Before diving into model selection, it’s essential to assess your operational needs:

- Load Requirements: Consider the typical weight and size of loads your forklift will handle.

- Environment: Determine whether the forklift will be used indoors, outdoors, or both.

- Operating Hours: Estimate how many hours per day the forklift will be in operation.

Forklift Types and Their ROI Impact

Choosing the right type of forklift is pivotal in maximizing ROI. Here’s how different forklifts stack up:

- Electric Forklifts: Ideal for indoor use due to zero emissions and low noise levels. Although the upfront cost is higher, the long-term savings on fuel and maintenance can be substantial.

- Internal Combustion Forklifts: Better suited for outdoor tasks. They offer robust performance and can handle uneven terrain and adverse weather conditions.

- Specialty Forklifts: Such as telescopic handlers or rough terrain forklifts, are crucial for specific jobs which standard forklifts cannot perform.

Case Study: Implementing Electric Forklifts

Scenario: A medium-sized distribution center switched from internal combustion to electric forklifts.

Results:

- Cost Savings: Reduced fuel costs by 70% annually.

- Increased Efficiency: Maintenance downtime decreased by 50% due to fewer mechanical issues.

- Environmental Impact: Significant reduction in carbon emissions.

ROI Calculation:

- Initial Investment: $20,000 more per forklift.

- Annual Savings: $10,000 in fuel, $5,000 in maintenance.

- Break-even Point: Just over 1 year.

Enhancing ROI Through Customization

Customizing forklifts to meet specific operational needs can further enhance ROI. Options include:

- Attachments: Adding specialized attachments like side shifters or paper roll clamps to increase versatility.

- Software Upgrades: Integrating fleet management software to track forklift usage and maintenance schedules.

Conclusion: Making the Right Choice

Selecting the right forklift involves balancing upfront costs with long-term benefits. By carefully evaluating your needs and understanding the different types of forklifts available, you can make an informed decision that not only meets your operational requirements but also maximizes your financial return.

This approach ensures that you invest in equipment that will provide the highest productivity and efficiency gains, tailored to your specific operational context.

Call to Action

Ready to explore the best forklift options for your business? Contact Bugle Forklift today to discuss your needs with our experts and find out how we can help you maximize your ROI with the perfect forklift selection.